3D Print Settings for ABS on Ender 3

Even with a hand made enclosure around my Ender 3 I was still struggling to get ABS to 3D print well – particularly for avoiding warping at the print bed. Here are the settings that worked well for me, printed great and reduced warping significantly:

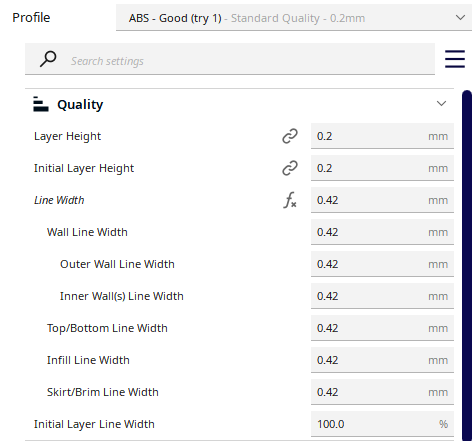

- Normal quality parameters (0.2mm)

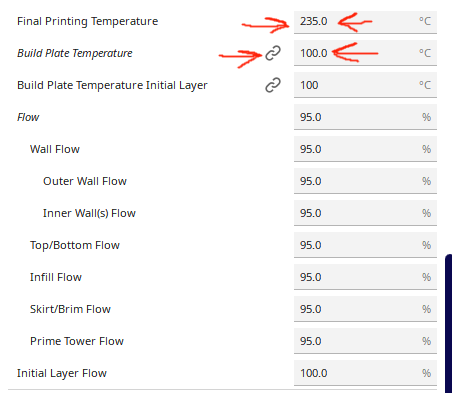

- Hot hot hot print temperatures – 235 nozzle, 100 build plate

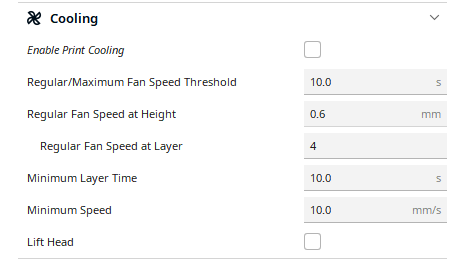

- No print cooling – just turn it off

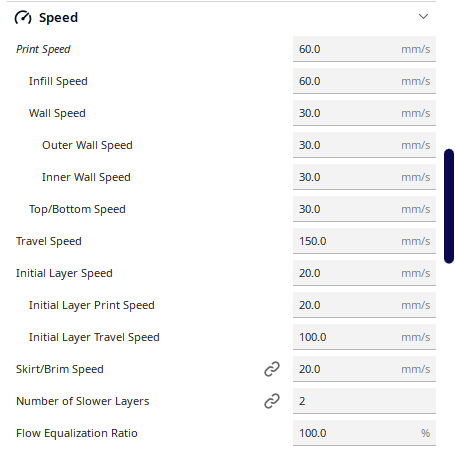

- fairly normal, if not a little bit slow printing speed

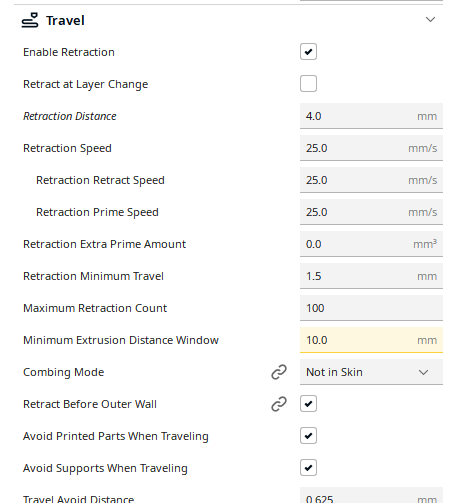

- small changes to extrusion and retraction distance

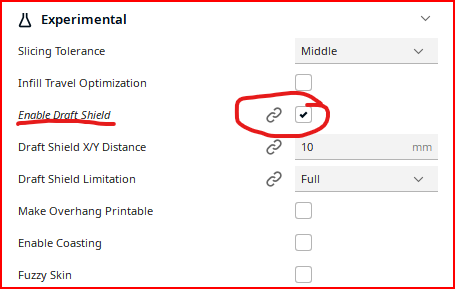

- Draft Shield – enabled in experimental section of Cura 5.0 – THIS MAKES THE BIGGEST DIFFERENCE

A few additional notes and thoughts, for those that are curious:

- My Ender 3 is totally stock. I haven’t upgraded anything yet (though I have capricorn tubing and an all metal hot end standing by for when something breaks)

- I have the magnetic print bed – i have done several ABS prints at 100 degrees C bed temperature – bed has not failed yet

- I do spray the bed with hair spray every half-dozen prints or so

- I have a DIY wood enclosure. I’ll write about it someday.

- I open a window in the room and set a fan to pull the air out – thats how I deal with ABS fumes – they are NASTY. My enclosure has not venting.

That’s it. So far so good – my ender 3 prints ABS and I am please with the results.